Weighing scales are essential tools in many sectors, including retail, agriculture, healthcare, laboratories, and industry. The two most common types are analog weighing scales and digital weighing scales. While both are used to measure weight, they differ significantly in how they work, their accuracy, ease of use, and suitability for modern commercial environments.

This article explains the key differences between analog and digital weighing scales to help you choose the right option for your needs.

1. What Is an Analog Weighing Scale?

Analog weighing scales are traditional mechanical scales that use springs or levers to measure weight. The weight is displayed using a needle or dial.

Key Features of Analog Scales:

- Mechanical operation (no electronics)

- Weight shown on a dial or pointer

- Do not require electricity or batteries

- Simple construction

Common Uses:

- Traditional markets

- Household use

- Basic weighing where high precision is not critical

2. What Is a Digital Weighing Scale?

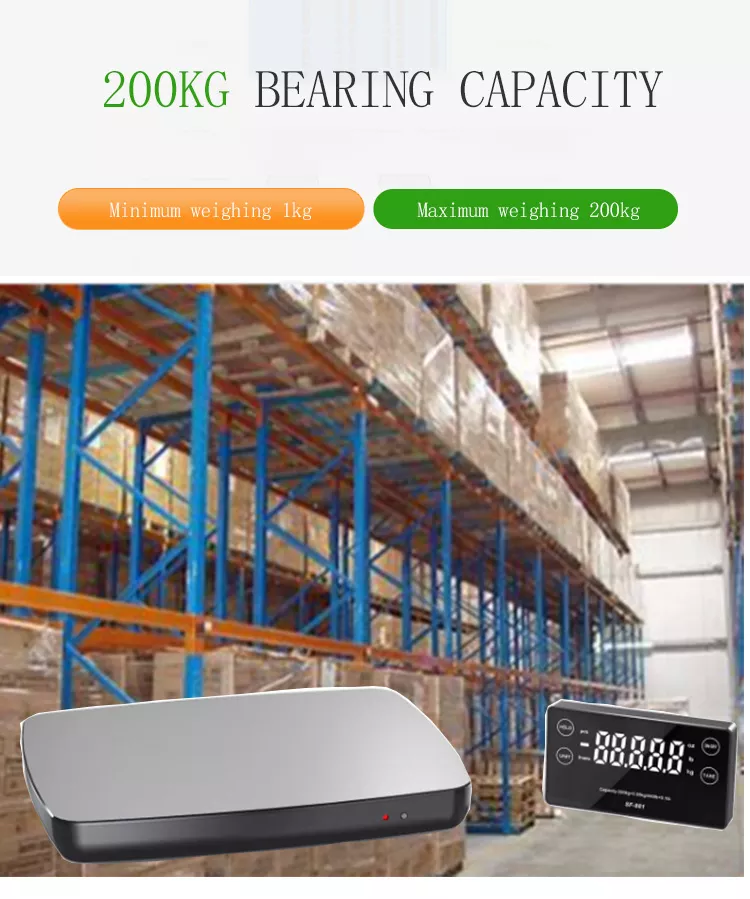

Digital weighing scales use electronic load cells to measure weight. The measurement is converted into an electrical signal and displayed on a digital screen.

Key Features of Digital Scales:

- Electronic operation

- Weight displayed clearly on an LCD or LED screen

- Require electricity or batteries

- Can include advanced functions such as tare, unit conversion, and data output

Common Uses:

- Commercial trade and retail

- Warehouses and logistics

- Industrial and laboratory applications

- Healthcare and food processing

3. Key Differences Between Analog and Digital Weighing Scales

|

Feature |

Analog Weighing Scales |

Digital Weighing Scales |

|

Accuracy |

Moderate |

High |

|

Display |

Needle or dial |

Digital screen |

|

Power Source |

Not required |

Batteries or electricity |

|

Ease of Reading |

Can be difficult |

Very easy and clear |

|

Maintenance |

Low but mechanical wear |

Requires electronic care |

|

Advanced Features |

Very limited |

Multiple features available |

|

Calibration |

Manual |

Easier and more precise |

|

Commercial Suitability |

Limited |

Highly suitable |

4. Accuracy and Reliability

- Analog scales can lose accuracy over time due to spring fatigue and mechanical wear.

- Digital scales offer more consistent and precise measurements, especially when regularly calibrated.

For businesses where pricing depends on weight, digital scales are generally the better option.

5. Ease of Use and Readability

Digital weighing scales provide clear numerical readings that reduce human error. Analog scales require users to interpret the needle position, which can lead to mistakes, especially in busy commercial environments.

6. Maintenance and Durability

- Analog scales are mechanically simple and can be robust in harsh environments.

- Digital scales, while more sensitive to moisture and power issues, are designed for durability in modern commercial and industrial settings.

With proper handling and regular calibration, digital scales offer long-term reliability.

7. Cost Considerations

- Analog weighing scales are usually cheaper upfront.

- Digital weighing scales may cost more initially but offer better accuracy, efficiency, and long-term value for businesses.

8. Which One Is Better for Commercial Use?

For most commercial applications today:

✅ Digital weighing scales are preferred due to their accuracy, speed, and advanced features.

⚠️ Analog weighing scales may still be useful for simple or non-critical weighing tasks.

Conclusion

The main difference between analog and digital weighing scales lies in their technology, accuracy, and usability. Analog scales are simple and do not require power, but they lack precision and modern features. Digital scales, on the other hand, provide higher accuracy, ease of use, and are better suited for commercial and industrial applications.

Choosing the right weighing scale depends on your business needs, accuracy requirements, and operating environment.